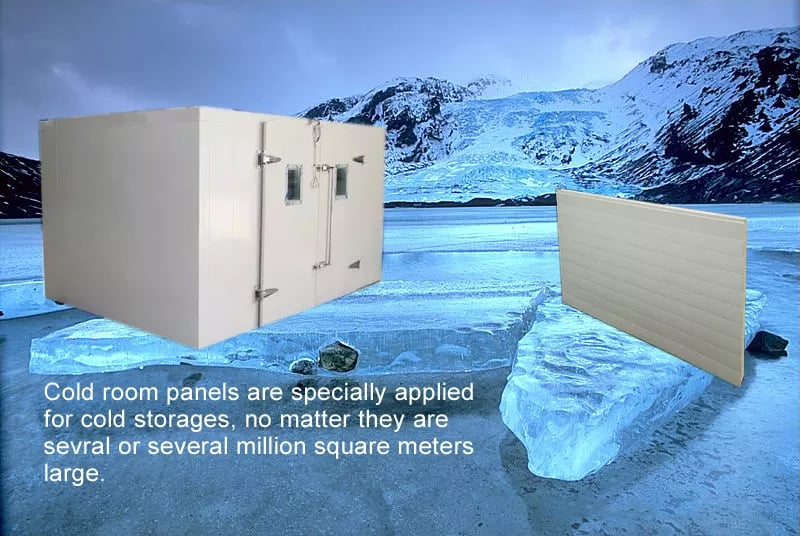

BRD cold rooms provide strong cooling for a variety of cold room sizes that cover applications ranging from medical lab storage rooms, food processing centers, walk-in coolers to drive-in distribution centers and others, which offer a wide range of solutions to preserve freshness, ensure safety and enhance the appearance of food and beverage retail.

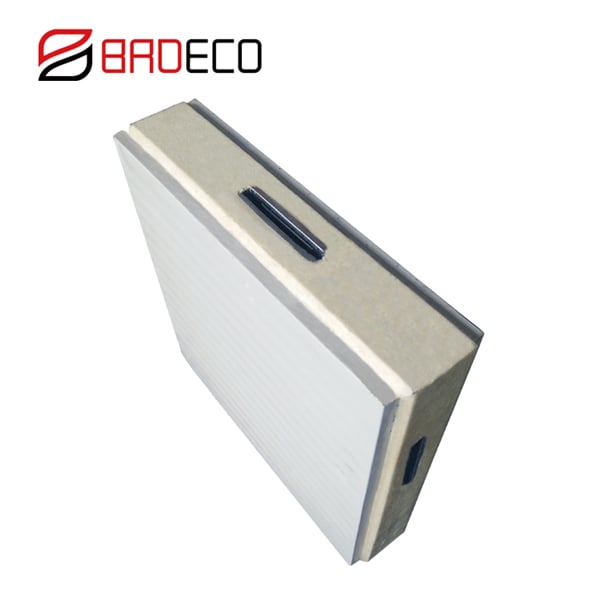

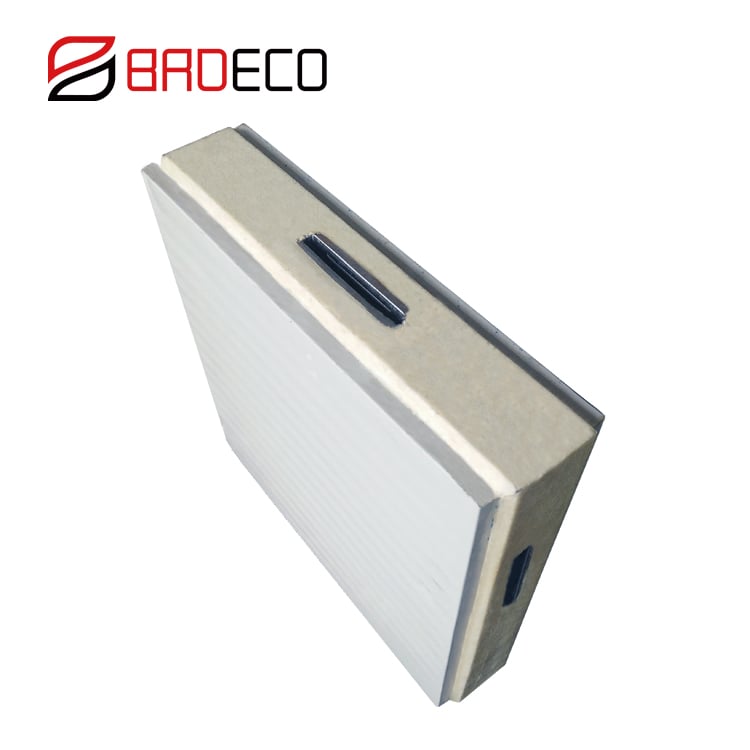

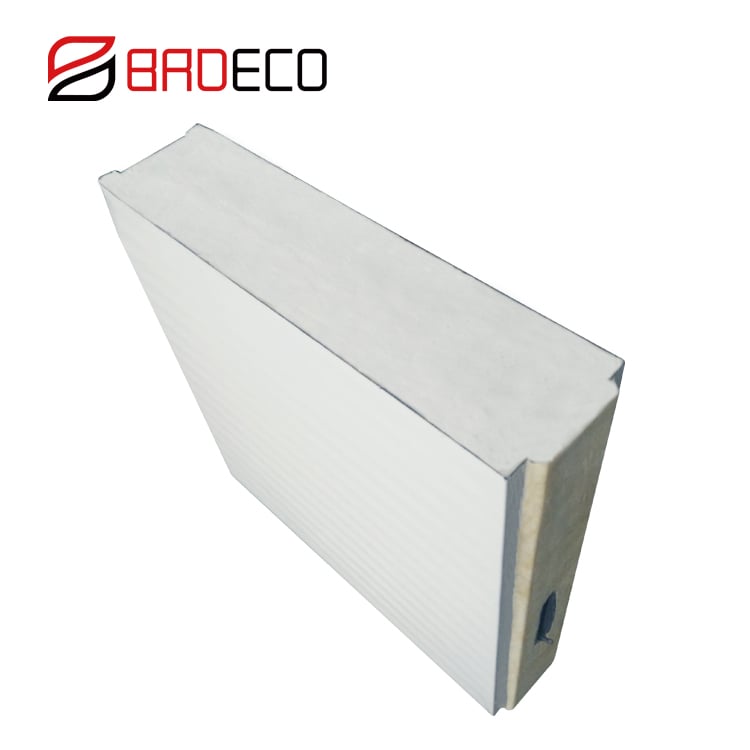

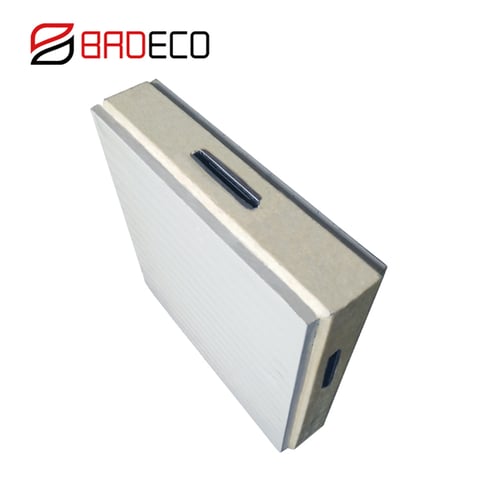

The polyurethane cold room panel is composed of two galvanized stee sheets and rigid polyurethane foam in the middle. Because the polyurethane cold room panel has several outstanding advantages, such as thermal insulation, waterproof, light weight and fast installation, It has been widely used as the building material of cold storages, cool rooms, clean rooms, free-dust workshops and exterior walls in cold places.

At present, BRD polyurethane cold room panel has five different thickness: 50mm, 75mm, 100mm, 150mm, 200mm.

Cold room panel is a new building material for cold storages and other buildings in cold places. It performs outstanding in aspects of thermal insulation and the waterproof, so it is widely accepted as a wonderful insulation building material. It is composed of two galvanized steel sheets and rigid polyurethane foam in the middle.

| Project | Temperature | Panel thickness |

| Processing room | 10℃ | 50mm |

| Fruit, vegetable, dry food | 0℃~-5℃ | 50mm |

| Medicine, cake, pastry, chemical material | 0℃~-5℃ | 75mm |

| Ice storage room | 5℃~-10℃ | 75mm |

| Fish, meat storage | -18℃~-25℃ | 150mm |

| Deep freezer | -25℃~-35℃ | 2000mm |

BRD Cold Room Panels are composed of 3 layers, the external and internal is galvanized sheet or Aluminum sheets, and core materials used high density polyurethane foam. Thanks to their good thermal insulation properties, it can be applied in projects that required very high heat insulation performanece, like cold storage, cool room ,freezer, refrigerating workshop construction.

|

Panel Thickness | 50, 75, 100, 125, 150, 200mm |

| Standard Facings |

Steel sheet coated with polyester paint, 25µm Hign Zinc sheet with Zn 50 – Zn 180g Stainless steel |

|

| Core Material Density | 40 [kg/m³] ±2kg/m³ | |

| Thermal Conductivity | 0.022 [W/mK] | |

| Acoustic Insulation | 30 [dB] | |

| Standard Length | 2m-12m | |

| Effective width | 500-1150mm | |

| Fire resistance | Non-flammable |

1, Good imported raw material: USA Huntsman.

2, Evenly foamed polyurethane: totally automatic production line.

3, Rather low air permeability: black seal strip gives an extra enhancement.

4, Strong adhesion: seperation will never happens on steel sheets and polyurethane foam.