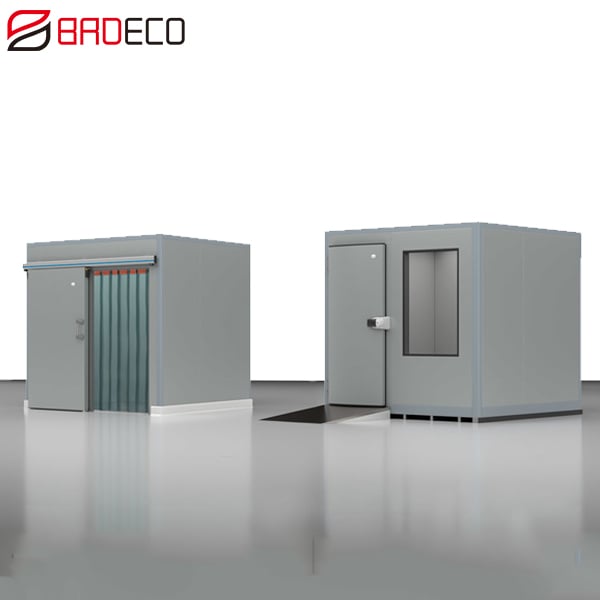

BRD cold rooms provide strong cooling for a variety of cold room sizes that cover applications ranging from medical lab storage rooms, food processing centers, walk-in coolers to drive-in distribution centers and others, which offer a wide range of solutions to preserve freshness, ensure safety and enhance the appearance of food and beverage retail.

BRD cold rooms provide strong cooling for a variety of cold room sizes that cover applications ranging from medical lab storage rooms, food processing centers, walk-in coolers to drive-in distribution centers and others, which offer a wide range of solutions to preserve freshness, ensure safety and enhance the appearance of food and beverage retail.

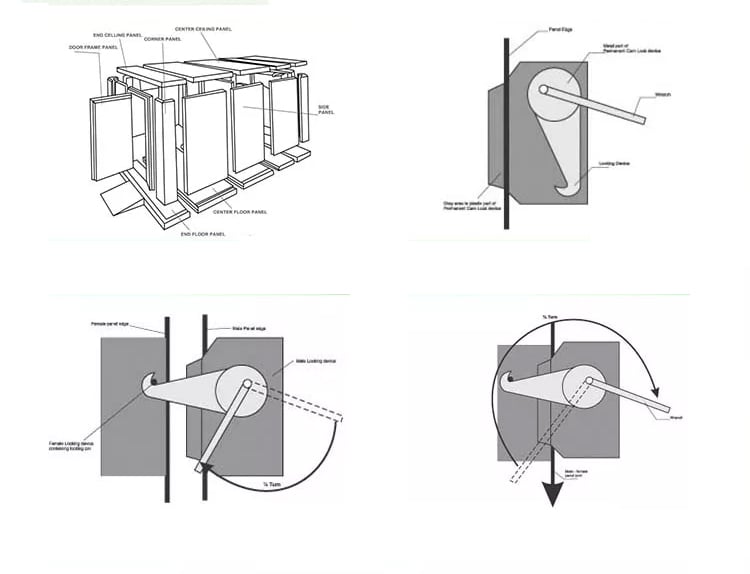

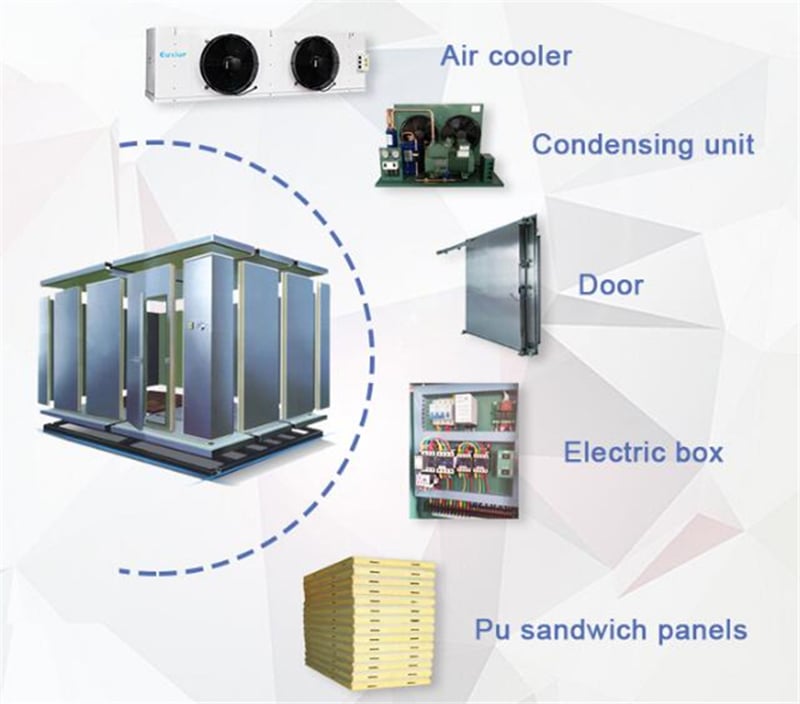

BRD cold room consists of cold room panel (PU sandwich panel), cold room door, condensing unit, evaporator (air cooler),temperature controller, air curtain, copper pipe, expansion valve and other refrigeration fittings.

| Project | Temperature | Panel thickness |

| Processing room | 10℃ | 50mm |

| Fruit, vegetable, dry food | 0℃~-5℃ | 50mm |

| Medicine, cake, pastry, chemical material | 0℃~-5℃ | 75mm |

| Ice storage room | 5℃~-10℃ | 75mm |

| Fish, meat storage | -18℃~-25℃ | 150mm |

| Deep freezer | -25℃~-35℃ | 2000mm |

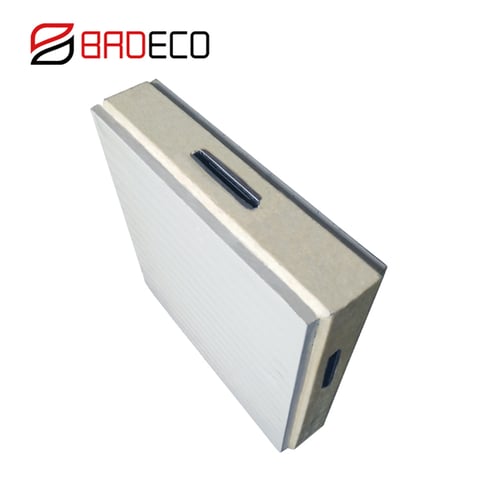

BRD Cold Room Panels are composed of 3 layers, the external and internal is galvanized sheet or Aluminum sheets, and core materials used high density polyurethane foam. Thanks to their good thermal insulation properties, it can be applied in projects that required very high heat insulation performanece, like cold storage, cool room ,freezer, refrigerating workshop construction.

|

Panel Thickness | 50, 75, 100, 125, 150, 200mm |

| Standard Facings |

Steel sheet coated with polyester paint, 25µm Hign Zinc sheet with Zn 50 – Zn 180g Stainless steel |

|

| Core Material Density | 40 [kg/m³] ±2kg/m³ | |

| Thermal Conductivity | 0.022 [W/mK] | |

| Acoustic Insulation | 30 [dB] | |

| Standard Length | 2m-12m | |

| Effective width | 500-1150mm | |

| Fire resistance | Non-flammable |

1.What is the application of the cold room?

It will affect the temperature of cold room needed to be, and the choice of thickness of pu panel and material covered on panel.

2.What is the size of the cold room?

It will affect the choice of condensing unit and air cooler, basing on the cold room temperature.

3.Which country will the cold room be located in? How about the climate?

It will affect the choice of voltage and condenser, if the temperature is high all the year, we need to choose condenser with bigger evaporation area.

Application scenarios:

BRD cold room systems are designed for usage within temperature controlled and hygiene safe environments such as, food processing, deep freeze, cold,chill store and cold storage for meat, food and other industries.

1.The combination of cold room is made of polyurethane cold storage panels which assembled into a room with evaporator and

cold.storage refrigeration system to control its inner temperature.

2.The polyurethane panel is light and with ingenious structure, convenient to assemble and operate,no need professional

technician;

3.With brand compressor which is forceful and has a long life span;

4.The operating system is stable and reliable with low failure rate and low noise.Its high efficiency refrigeration system saves

much electricity;

5.We could custom-made as per your requests,we could make the inner temp. between 10℃ to -50℃.